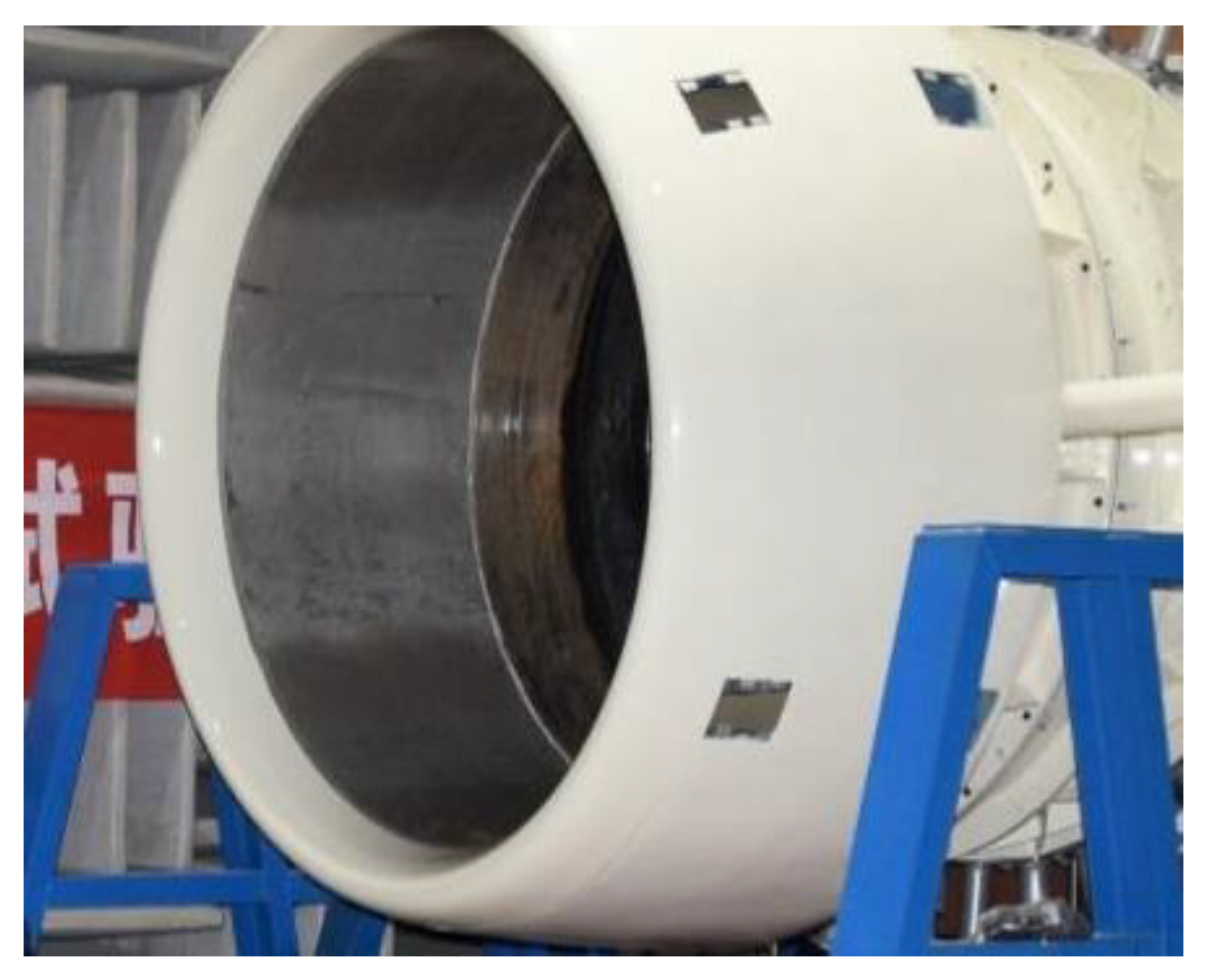

Aircraft Nacelle - Nacelle: interface between engine and aircraft; large systems and high-tech equipment

Parts are one of the most visible elements of an aircraft, but should be recognized for their primary propulsion function and critical contribution to aircraft performance.

Aircraft Nacelle

Acting as the link between the engine and the aircraft, the landing gear is considered an aircraft structure, but it is effectively a high-tech component with many functions.

H3 Dynamics Completes World's First Flight With Proprietary Distributed Hydrogen Electric Nacelle Technology

It contains the engine, helps with its ventilation and thermal regulation in extreme temperature conditions, is protected by steel, but allows easy access through a closed door for maintenance and repair. The cowl directs both primary and secondary airflow to the engine, which is important for optimizing thrust. In addition, it plays an important role in noise reduction thanks to precise acoustic processing using composite and metal materials. It contributes to the safe braking of the aircraft during landing by installing the rotational component of the aircraft engine. Finally, engine and fluid transfer is provided through tubes and connections for electrical, hydraulic, pneumatic, and fuel flow between the engine and the aircraft - accomplished by Engine Installation Unit (EBU) equipment.

Its highly refined aerodynamic shape and careful weight management directly contribute to lower fuel consumption and reduced emissions. The lever-turning device performs an important safety function: it shortens the braking distance during landing and ensures perfect control of the aircraft regardless of the weather conditions and the runway. The materials used to build the ship and the acoustic treatment incorporated throughout the main interior. by reducing surface areas and engine noise, it makes the aircraft more suitable for the airport and provides a better environment for passengers in the cabin. Both the quad-engine A380 super jumbo and the twin-engine A320neo single-aisle jets use Safran Nacelles, which are capable of halving in-flight noise. Finally, component reliability and durability allow airlines to reduce maintenance and repair costs.

Designing and manufacturing such complex multifunctional equipment requires advanced technical skills in many design areas such as materials, aerodynamics, acoustics, thermodynamics, mechanical loads, hydraulics and electrical systems... In addition, manufacturers such as Safran Nacelles have robust and competitive equipment. production process is necessary. Integration capabilities are based on a consistent level of innovation, a deep understanding of aircraft engines and aircraft interactions, as well as comprehensive knowledge of certification requirements to ensure passenger and aircraft safety.

Safran Nacelles is one of the few car manufacturers in the world that has all these capabilities. We have more than 40 years of unique experience in the various functions we organize every day, especially in all our operational processes. the world's largest space programs for commercial and regional aviation and business aircraft. Precision instrumentation, augmented reality, virtual reality, automation and destructive testing technologies have become commonplace in our design offices, factories and repair shops. We support operators every day by continuously improving quality and excellence through our product design and manufacturing. The result was a 12-month development cycle for our competing Airbus A330neo jet, shortened from the standard time for a program of this size.

Gulfstream, Nordam Reach Deal On Pw800 Nacelles

We have also developed major innovations such as electric actuators for the thruster rotors (originally fitted to the A380) and more recently the one-piece O-Duct thruster rotor (for the COMAC C919 jet) which is a full leap over other standard models. . For nearly 20 years, starting with the Airbus 340-500/600 program, we have used digital simulation to visualize the interactions between engines, engines and aircraft to ensure superior unit performance. Finally, our NacelleLifeTM service offering enables our customers to optimize their operating costs by providing high-quality, cost-effective support throughout the lifetime of their aircraft.

Furthermore, as a member of Safran, a world leader in space and aerospace equipment, we are proud to be part of a company with access to global experience and exceptional know-how beyond our aircraft manufacturing capabilities. It starts with Safran, from the aircraft engine center of excellence to aircraft engine operations, making Safran a complete "engineering system" for a more integrated engine system.

These achievements are the real pride of our 4000 employees. In addition, they are the source of our customers' satisfaction and success.

This is the reason why they trust us. The numbers speak for themselves: 230 airline customers, 21,700 products in service, 1 thrust reverse deployment cycle every 1.3 seconds... We are more ready than ever to meet new challenges to support all aircraft in the aviation industry. working with engine manufacturers, customers and operators to provide and maintain engine equipment for our latest engines. Not surprisingly, one of the dirtiest parts of a jet is the engine. Engines have come a long way since the jet age, but they produce a lot of carbon. Of course, carbon is the main cause of corrosion, but it can cause more problems in an engine than that. Modern engine cases are great designs that do more than house the engine; They are aerodynamic marvels that direct the airflow from the engine and accommodate the engine's additional drive system. Not surprisingly, pits are a dirty place, but a sensitive one.

File:f 14a Tomcat Port Engine Nacelle.jpg

In this first installment of the best engine maintenance, we'll look at the various parts of the front of the engine, why they need to be cleaned regularly, and how these products can be the perfect addition to your cleaning schedule. washing cycle.

The engine is an engineering marvel. On the surface, they don't look like it at all, but they are complex and finely tuned engine components. More than just a cushion to hang the engine on, the engine bay is an aerodynamic marvel that reduces noise, saves fuel and promotes cleaner combustion of fuel and air.

In the early days of jet aircraft, jet engines were of turbojet design. Turbojet engines consist of a main engine; There was no fan stage to bypass the air as in modern jet aircraft.

Turbojets were very loud and extremely inefficient, but the development of new engine technology was necessary.

World's First' Hydrogen Aircraft Propulsor Nacelle Set To Power Long Haul Flights

Modern jet aircraft (except military tactical jets) are all powered by high-revving turbofan engines. These are basically cores (all turbojets used to be), but have fan blade stages at the front of the engine. The fan section produces about eighty percent of the compression, and the rest is transferred from the turbojet core of the engine. The valves installed on later turbofans were designed to pass most of the air through the tail cone exhaust.

Turbofan engines have fixed geometry fan blades and are highly efficient. However, since they are not adjustable, you need to have a way to smooth the airflow and direct it to the fan sections. That's what shell lips are designed for.

The valve is where the bird hits the most or makes the most mistakes. Aviationprep wipes are a great addition to the ground crew's toolbox to prevent lip-smacking bugs between washes.

Fortunately for today's jet aircraft, the propeller blades of a jet engine emit no smoke. The air is clean and this flow helps to cool the engine core. The cowling usually consists of two parts: an access panel for additional systems and the actual engine duct.

Aircraft Engine Nacelle With Translating Inlet Cowl

Let's talk about "worms" for a moment. Oh, you're not familiar with that term? Snarge is a general term for the remains of small animals or birds (usually birds) after being swallowed by an engine.

Bird traps are ugly. It sticks to surfaces like you wouldn't believe when it hits the fan blade. If you think that's too much, it's not. Bird strikes are a common occurrence in the aviation industry and can cause significant damage. how much

When your plane hits a bird, you have to clean the wings from all surfaces, not an easy task. Your best bet for cleaning bird droppings is a good general-purpose, non-flammable cleaner (especially important for cleaning fan blades). Another useful tool is a wipe for cleaning and preparation. Not every birdie strike is a big event; Sometimes it's just a little dab and a swipe will do the trick.

Now we come to the main issue. The back of the motor is mounted behind the shaft,

An Aviation Milestone: Safran Nacelles Delivers Its 100th Nacelle For Airbus A320neo Jetliners

Nacelle genie, aircraft engine nacelle, nacelle mobile, road king headlight nacelle, aircraft nacelle design, location de nacelle, location nacelle prix, nacelle skyjack, nacelle, nacelle harley davidson, formation nacelle, location nacelle

0 Comments